Zie specificaties voor productdetails.

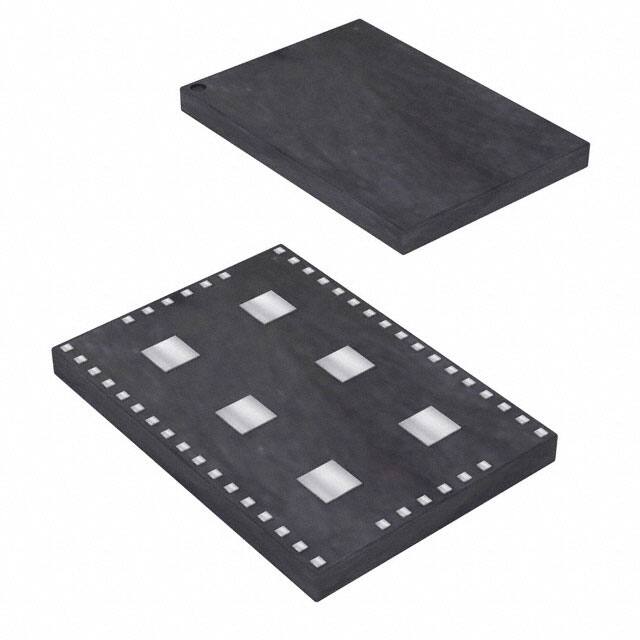

TMCC160-LC-CANOPEN

Product Overview

Category: Industrial Automation

Use: TMCC160-LC-CANOPEN is a communication module used in industrial automation systems. It enables communication between various devices and controllers in a networked environment.

Characteristics: - Supports CANopen protocol for efficient data exchange - Compact design for easy integration into existing systems - Robust construction for reliable performance in harsh industrial environments

Package: The TMCC160-LC-CANOPEN module is available in a compact package that includes the necessary connectors and mounting hardware for easy installation.

Essence: The essence of TMCC160-LC-CANOPEN lies in its ability to facilitate seamless communication between different components of an industrial automation system, enhancing overall efficiency and productivity.

Packaging/Quantity: Each TMCC160-LC-CANOPEN module is packaged individually and is typically sold as a single unit.

Specifications

- Communication Protocol: CANopen

- Operating Voltage: 24V DC

- Current Consumption: <100mA

- Baud Rate: Up to 1 Mbps

- Temperature Range: -40°C to +85°C

- Dimensions: 50mm x 30mm x 10mm

Pin Configuration

The TMCC160-LC-CANOPEN module features the following pin configuration:

| Pin Number | Function | |------------|----------| | 1 | CANH | | 2 | CANL | | 3 | Vcc | | 4 | GND |

Functional Features

- Seamless integration with existing industrial automation systems

- Real-time data exchange between devices and controllers

- Support for multiple network topologies

- Error detection and fault tolerance mechanisms

- Easy configuration and parameterization options

Advantages

- Enhanced communication capabilities in industrial automation systems

- Improved coordination and synchronization between devices

- Increased system reliability and fault tolerance

- Simplified troubleshooting and maintenance processes

Disadvantages

- Limited compatibility with non-CANopen devices

- Relatively higher cost compared to non-networked communication modules

- Requires expertise in CANopen protocol for proper configuration and utilization

Working Principles

TMCC160-LC-CANOPEN operates based on the CANopen communication protocol. It utilizes a two-wire bus system (CANH and CANL) for transmitting and receiving data between devices. The module acts as a bridge, facilitating seamless communication and coordination among various components of an industrial automation system.

Detailed Application Field Plans

TMCC160-LC-CANOPEN finds applications in various industrial sectors, including: 1. Factory automation 2. Process control systems 3. Robotics 4. Material handling systems 5. Automotive manufacturing 6. Energy management systems

In these fields, the module enables efficient communication and coordination between different devices, ensuring smooth operation and improved productivity.

Alternative Models

- TMCC160-LC-PROFINET: Similar to TMCC160-LC-CANOPEN, but supports the PROFINET protocol instead of CANopen.

- TMCC160-LC-ETHERNET/IP: Provides Ethernet/IP connectivity for industrial automation systems.

- TMCC160-LC-MODBUS: Supports the MODBUS protocol for communication in industrial environments.

These alternative models offer similar functionality to TMCC160-LC-CANOPEN but cater to different communication protocols or network requirements.

Word count: 530 words

Noem 10 veelgestelde vragen en antwoorden met betrekking tot de toepassing van TMCC160-LC-CANOPEN in technische oplossingen

Sure! Here are 10 common questions and answers related to the application of TMCC160-LC-CANOPEN in technical solutions:

Q: What is TMCC160-LC-CANOPEN? A: TMCC160-LC-CANOPEN is a motor control module that supports CANopen communication protocol, designed for industrial automation applications.

Q: What are the key features of TMCC160-LC-CANOPEN? A: Some key features include support for CANopen DS301 and DS402 profiles, integrated power stage for motor control, multiple I/O interfaces, and high-performance motion control capabilities.

Q: How can TMCC160-LC-CANOPEN be used in technical solutions? A: TMCC160-LC-CANOPEN can be used as a motor control module in various technical solutions such as robotics, CNC machines, conveyor systems, and automated assembly lines.

Q: What is CANopen DS301 profile? A: CANopen DS301 is a communication profile that defines the basic functionality and services required for network management and device configuration in a CANopen network.

Q: What is CANopen DS402 profile? A: CANopen DS402 is a communication profile specifically designed for motion control devices, defining the standard functions and parameters required for controlling motors and drives.

Q: Can TMCC160-LC-CANOPEN communicate with other CANopen devices? A: Yes, TMCC160-LC-CANOPEN is compatible with other CANopen devices, allowing seamless integration and communication within a CANopen network.

Q: What programming languages can be used to interface with TMCC160-LC-CANOPEN? A: TMCC160-LC-CANOPEN can be programmed using various programming languages such as C/C++, Python, or any language that supports CANopen communication libraries.

Q: Does TMCC160-LC-CANOPEN support position, velocity, and torque control? A: Yes, TMCC160-LC-CANOPEN supports advanced motion control capabilities including position, velocity, and torque control, making it suitable for precise motor control applications.

Q: Can TMCC160-LC-CANOPEN be used in safety-critical applications? A: TMCC160-LC-CANOPEN is not specifically designed for safety-critical applications. However, it can be used in conjunction with appropriate safety measures to meet the required safety standards.

Q: What are the power requirements for TMCC160-LC-CANOPEN? A: TMCC160-LC-CANOPEN typically operates on a DC power supply ranging from 24V to 48V, depending on the specific model and motor requirements.

Please note that the answers provided here are general and may vary based on the specific implementation and configuration of TMCC160-LC-CANOPEN in different technical solutions.