Zie specificaties voor productdetails.

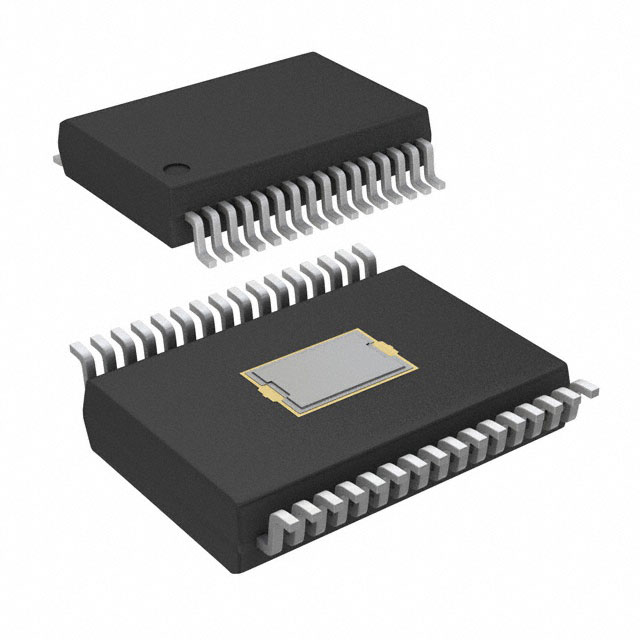

MC33HB2001EK

Product Overview

Category

MC33HB2001EK belongs to the category of motor driver integrated circuits.

Use

It is primarily used for controlling and driving DC motors.

Characteristics

- High efficiency

- Low power consumption

- Compact size

- Reliable performance

Package

MC33HB2001EK is available in a compact package, suitable for easy integration into various electronic systems.

Essence

The essence of MC33HB2001EK lies in its ability to provide efficient and reliable control for DC motors.

Packaging/Quantity

This product is typically packaged in reels or tubes, with a quantity of 2500 units per reel/tube.

Specifications

- Operating Voltage: 2.5V - 5.5V

- Output Current: Up to 1.5A

- Number of Channels: 1

- Control Interface: PWM

- Protection Features: Overcurrent, Overtemperature, Undervoltage lockout

Detailed Pin Configuration

- VCC: Power supply voltage input

- GND: Ground reference

- IN1: Input control signal 1

- IN2: Input control signal 2

- OUT: Motor output

- FAULT: Fault detection output

- VREF: Reference voltage output

- EN: Enable control input

Functional Features

- Single-channel H-bridge configuration

- PWM-based speed control

- Fault detection and reporting

- Overcurrent protection

- Thermal shutdown protection

- Undervoltage lockout

Advantages

- High efficiency operation

- Low power consumption

- Compact size for space-constrained applications

- Reliable performance under varying load conditions

- Comprehensive protection features ensure system safety

Disadvantages

- Limited to single-channel motor control

- May require additional external components for certain applications

Working Principles

MC33HB2001EK utilizes a single-channel H-bridge configuration to control the direction and speed of a DC motor. The control signals received at IN1 and IN2 determine the motor's rotation direction, while the PWM signal applied to the EN pin regulates the motor speed. The integrated protection features ensure safe operation by monitoring current, temperature, and voltage levels.

Detailed Application Field Plans

MC33HB2001EK finds extensive application in various fields, including:

- Robotics: Controlling motors in robotic systems for precise movement and manipulation.

- Automotive: Driving small motors in automotive subsystems such as power windows, mirrors, and seat adjustments.

- Consumer Electronics: Motor control in appliances like fans, air conditioners, and home automation systems.

- Industrial Automation: Motor control in conveyor belts, pumps, and other industrial machinery.

Detailed and Complete Alternative Models

- MC33HB2000EK

- MC33HB3001EK

- MC33HB4001EK

- MC33HB5001EK

These alternative models offer similar functionality and can be considered based on specific application requirements.

In conclusion, MC33HB2001EK is a highly efficient and compact motor driver IC designed for controlling DC motors. Its comprehensive features, reliable performance, and wide range of applications make it a popular choice in various industries.

Noem 10 veelgestelde vragen en antwoorden met betrekking tot de toepassing van MC33HB2001EK in technische oplossingen

Sure! Here are 10 common questions and answers related to the application of MC33HB2001EK in technical solutions:

Q1: What is MC33HB2001EK? A1: MC33HB2001EK is a motor driver IC designed for automotive applications, capable of driving one DC motor or two bidirectional DC motors.

Q2: What is the maximum voltage rating of MC33HB2001EK? A2: The maximum voltage rating of MC33HB2001EK is typically 40V.

Q3: How much current can MC33HB2001EK handle? A3: MC33HB2001EK can handle a continuous output current of up to 1.5A per channel.

Q4: Can MC33HB2001EK control stepper motors? A4: No, MC33HB2001EK is specifically designed for DC motors and cannot directly control stepper motors.

Q5: Does MC33HB2001EK have built-in protection features? A5: Yes, MC33HB2001EK includes various protection features like overcurrent protection, thermal shutdown, and under-voltage lockout.

Q6: Can MC33HB2001EK operate in both forward and reverse directions? A6: Yes, MC33HB2001EK supports bidirectional control, allowing operation in both forward and reverse directions.

Q7: What is the operating temperature range of MC33HB2001EK? A7: The operating temperature range of MC33HB2001EK is typically -40°C to +125°C.

Q8: Is MC33HB2001EK suitable for automotive applications? A8: Yes, MC33HB2001EK is designed for automotive applications and meets the necessary requirements for such environments.

Q9: Can MC33HB2001EK be used with microcontrollers? A9: Yes, MC33HB2001EK can be easily interfaced with microcontrollers using standard digital control signals.

Q10: Does MC33HB2001EK require external components for operation? A10: Yes, MC33HB2001EK requires external components like power supply, motor connections, and decoupling capacitors for proper operation.

Please note that these answers are general and may vary depending on the specific application and requirements.