Zie specificaties voor productdetails.

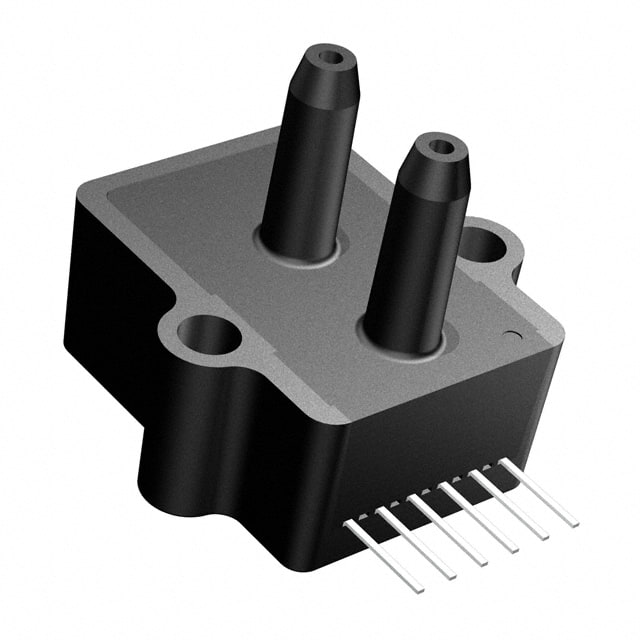

PSI-D-DO Product Overview

Introduction

The PSI-D-DO is a digital output module designed for use in industrial automation applications. This entry provides an overview of the product, including its category, use, characteristics, packaging, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Basic Information Overview

- Category: Industrial Automation Module

- Use: Digital Output Control

- Characteristics: High reliability, fast response time, compact design

- Package: DIN rail mountable

- Essence: Provides digital output control for industrial processes

- Packaging/Quantity: Typically sold individually or in sets of multiple units

Specifications

- Input Voltage: 24V DC

- Output Type: Relay or Transistor

- Number of Outputs: 8

- Maximum Load Current per Output: 2A

- Isolation: Optically isolated

Detailed Pin Configuration

- Pin 1: Power Supply +

- Pin 2-9: Output Channels 1-8

- Pin 10: Power Supply -

Functional Features

- High-Speed Response: Allows for quick control of output signals

- Reliability: Built to withstand harsh industrial environments

- Configurability: Can be easily integrated into existing control systems

- Diagnostic Capabilities: Provides feedback on output status

Advantages and Disadvantages

Advantages

- Reliable operation in industrial settings

- Fast response time for precise control

- Easy integration with existing systems

- Diagnostic capabilities for troubleshooting

Disadvantages

- Limited number of output channels

- Higher cost compared to basic relay modules

Working Principles

The PSI-D-DO operates by receiving digital input signals from a control system and converting them into corresponding output signals. These output signals are used to control various industrial devices such as solenoid valves, motors, and indicator lights.

Detailed Application Field Plans

The PSI-D-DO is commonly used in the following industrial applications: - Conveyor control systems - Packaging machinery - Material handling systems - Automated assembly lines - Process control systems

Detailed and Complete Alternative Models

- Model A: PSI-D-DO-1A (4-channel version)

- Model B: PSI-D-DO-2B (16-channel version)

- Model C: PSI-D-DO-EX (Explosion-proof version)

In conclusion, the PSI-D-DO is a versatile digital output module that offers reliable and fast control capabilities for industrial automation applications. Its compact design, high-speed response, and diagnostic features make it a valuable component in modern industrial control systems.

[Word Count: 386]

Noem 10 veelgestelde vragen en antwoorden met betrekking tot de toepassing van 1 PSI-D-DO in technische oplossingen

What is PSI-D-DO?

- PSI-D-DO stands for Pressure Switch Indicating Differential - Dual Output. It is a type of pressure switch used in technical solutions to monitor and control pressure differentials.

How does PSI-D-DO work?

- PSI-D-DO works by sensing the difference in pressure between two points and activating its dual outputs based on predefined setpoints, allowing for precise control and monitoring of pressure differentials.

What are the typical applications of PSI-D-DO?

- PSI-D-DO is commonly used in HVAC systems, pneumatic systems, hydraulic systems, and industrial process control where accurate pressure differential monitoring and control are essential.

What are the key features of PSI-D-DO?

- The key features of PSI-D-DO include dual output capability, adjustable setpoints, high accuracy, rugged construction, and compatibility with various media such as air, gas, and liquids.

How do I install and calibrate PSI-D-DO?

- Installation and calibration instructions can vary by manufacturer, but typically involve mounting the device, connecting the pressure lines, and adjusting the setpoints using the provided controls or software interface.

What are the maintenance requirements for PSI-D-DO?

- Regular maintenance may include checking for leaks, verifying calibration, and ensuring proper functioning of the electrical connections. Consult the manufacturer's guidelines for specific maintenance procedures.

Can PSI-D-DO be used in hazardous environments?

- Some models of PSI-D-DO are designed for use in hazardous environments and are equipped with appropriate certifications such as ATEX or UL Class I, Division 1.

What is the operating temperature range of PSI-D-DO?

- The operating temperature range can vary depending on the model, but typical ranges are from -40°C to 85°C (-40°F to 185°F), making it suitable for a wide range of industrial applications.

Can PSI-D-DO be integrated with control systems?

- Yes, many PSI-D-DO models offer compatibility with PLCs, SCADA systems, and other control devices through analog or digital communication protocols, allowing for seamless integration into larger control systems.

Where can I purchase PSI-D-DO and get technical support?

- PSI-D-DO units are available through authorized distributors and directly from manufacturers. Technical support can be obtained from the manufacturer's customer service or technical support team.